Tents in Strong Wind: What You Need to Know

Ominous skies above Landmannalauger in Central Iceland the evening before a storm. You can see our lonely little non-freestanding Duplex amongst a sea of freestanding tents.

Wind and Tents – no, not the horrific wind inside after too many dehydrated meals! – but the wind outside your tent!

Strong winds can ruin your trip. They break poles, rip flies and pull out pegs, collapsing your shelter. Driven rain often accompanies strong winds so, when your tent fails, your gear gets drenched and cuts short your holiday. At best you’ll have a miserable night, at worst hypothermia or even death.

Perhaps you’re not heading into extreme conditions, but they develop unexpectedly and then you’re stuck in them: you are who this article is aimed at, rather than those who regularly camp in stormy weather or at altitude. Understanding wind, tents and terrain can make the difference between an enjoyable hike or a terrible one so, with a little help from tent manufacturers, we’ve written this in-depth, three-part article to help you get the most out of your tent in strong winds and storms.

Part 1 describes the physics of wind and how it impacts different tents.

Part 2 covers the wind’s interaction with terrain so you can identify optimal pitches, and

Part 3 provides tips on how to pitch and anchor your tent before and during strong wind to best withstand its force.

Settle in for a relaxed read with plenty of pictures and video links!

‘There I was in a Hurricane’ Hiker Stories

If you’re in any online hiking community, you’ll have seen descriptions of tents surviving gales of up to [50 knots, 60 mph, 100 kph or 30 metres per second]. While some of these situations are accurate, many – perhaps most – are not. This isn’t because hikers are deliberately exaggerating, but because we humans rarely judge windspeed accurately, and because most of us don’t understand how wind behaves.

For example, we may extrapolate readings from the tower at the top of the hill while we’re camped at the base of the tower, or a metre below the ridge, or in the lee, amongst scattered bushes, trees or rocks, or in tall grass. We interpret television weather reports to accurately reflect the exact speed our tent experienced in its specific location. And many of us don’t realise that the relationship between wind speed and wind force is not linear but quadratic.

Geoff and I have been hang glider pilots for more than two decades. What can this possibly have to do with camping? Well, quite a lot actually, especially camping in wind!

Geoff coming in to land at our local flying site before the rain - and change in wind - arrive.

Together with paragliders, hang gliders are the butterflies of the aircraft world. Pilots fly in a narrow speed envelope, above which we are at the mercy of the wind, tossed like those butterflies in a gale, unable to bring our craft to a stop until terrain does it for us, usually catastrophically.

Turbulent air created by terrain can also flick us upside down or splat us into the ground. Not only that, but we often fly within a couple metres of bushes and cliffs. There is literally no room for error.

For these reasons, hang glider pilots develop not only the ability to accurately judge wind speed up to around 30 knots, but also an understanding of how wind behaves around terrain, where it speeds or slows, and where it is turbulent or smooth.

As well, our craft comprise aluminium or carbon frames covered in materials similar to yacht sails… and today’s high-end tents. We understand the wind’s power and its relationship to our wing (and tent) surfaces, because angling your craft incorrectly by just a few degrees while groundhandling can easily over-ride your control. Yachties have similar skills across a much wider range of wind speeds than we do but are less experienced in the effects of terrain.

It’s no coincidence these hangliders are all parked in the same way: get it wrong and your expensive glider will go for a little flight all by itself without you in it, and it will not end cheaply! Can you guess the wind direction? Hint: they are parked to shed wind to reduce forces on the back of the sail. Note the aluminium frames and mylar/dacron fabrics.

1. Understanding Wind Speed and Force

First, some useful physics. Don’t be daunted: Geoff simplified it so even I could understand, so give it a go! Or scroll down to the applied physics, 2. Tent Characteristics.

Wind exerts a dynamic force on obstacles as it moves across land from areas of higher pressure to areas of lower pressure. Wind speed is, of course, how fast the wind is travelling.

The magnitude of the force the wind exerts can be calculated via Newton’s Second Law of Motion:

Force = mass x acceleration. The unit of force is Newtons.

By assuming our tent stays still and the wind is stopped by the tent, the force is calculated by the mass of the wind acting on the surface of the tent and its acceleration, which can be estimated as the square of the wind speed.

There are two key points:

1) The force on the tent is related to the square of the windspeed. The relationship is not linear, but quadratic ie Force is proportional to Wind Speed squared.

So, if wind speed doubles, the force quadruples.

And that’s why it’s so easy to misjudge wind speed: the wind feels four times as fast, when it is only twice as fast.

Here’s a graph of this relationship:

Figure 1: The relationship between wind speed and its force is not linear.

So, when a wind of 18 knots (a fresh breeze on the Beaufort Scale) doubles to 36 knots (a Gale) the force increases from 108 Newtons to 432 Newtons.

Or, if we increase the wind speed from 10 knots to 40 knots, a factor of four, our potential load increases from 32 Newtons to 512 Newtons, a factor of 16 (4 squared)! Your tent needs to be not 4 times but 16 times more wind resistant!

Newtons law also refers to the mass of the object. In our case the “object” being stopped is the wind itself.

2) The mass of wind acting on the surface of the tent is equivalent to the density of air times the effective area perpendicular to the direction of travel of the wind (ie the area over which the wind is exerting force on the tent).

If our tent is a box and the wind is travelling horizontally, then the effective area is the surface area of the box facing the wind as in Case A.

Fig 2: Force Relative to Surface Area

If the box is at an angle, as in case B, it’s still the area perpendicular to the wind – but this time it’s slightly larger, as illustrated by the red outline.

Newton doesn’t have it all sorted because the wind isn’t stopped by the obstruction, just changed in its direction.

Another physicist, Bernoulli, developed a law of fluid/gas flow based on the conservation of energy.

Bernoulli’s theory uses the following equation to calculate wind force:

Wind Force = Coefficient x (air density x effective area x wind speed x wind speed)/2

This formula is the basis for most engineering calculations for wind loads on structures because estimated loads are more realistic (and smaller).

The coefficient in the front of the equation is empirical and different industries apply varying levels of complexity to its derivation – large tent manufacturers might even have their own. In its simplest real-world form, the coefficient accounts for the object’s shape and the roughness of surrounding terrain.

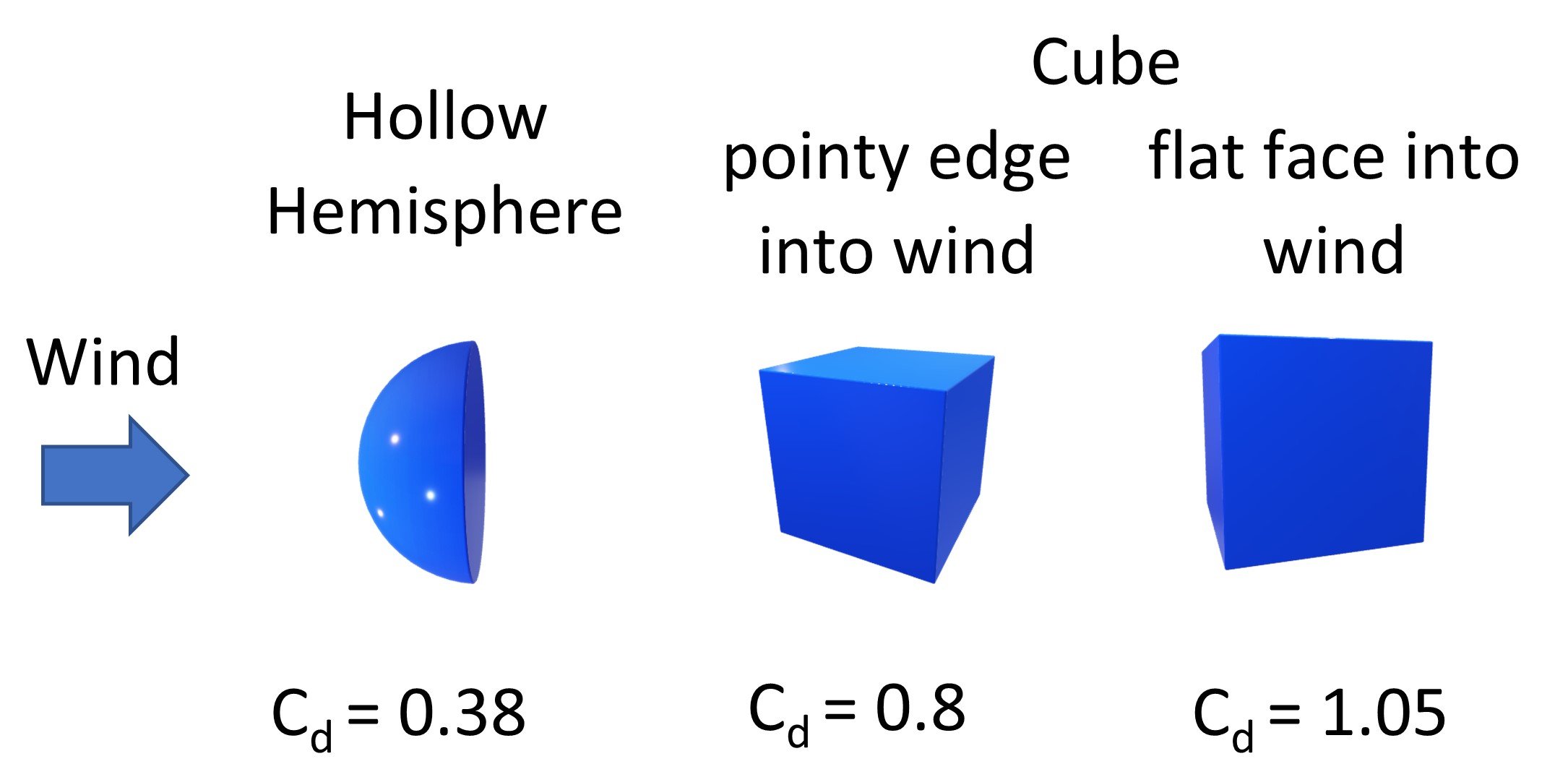

Bernoulli’s work is useful for us campers because he explains the effect of the object’s shape on the force that will apply to it, quantified through thousands of wind tunnel and laboratory tests to estimate the drag coefficient (Cd) for differently-shaped objects. The drag coefficient forms part of our coefficient in the force equation.

The bigger the drag coefficient the higher the force, but at least this relationship is linear, so if you halve the coefficient you halve the force.

Here are a couple of examples assuming different three-dimensional shapes:

Fig 3: Drag relative to Shape (Source: Drag coefficient - Wikipedia)

We all intuitively know shape is important, but comparing coefficients for different configurations clarifies how significant it can be.

In our Case B previously, (Fig 2), by rotating the box (tent) with the pointy end into the wind we actually increase the exposed area, and hence the force (the red diagonal is larger than one face of the box) but this is offset by the pointy edge of the box deflecting the wind and reducing drag rather the flat face blocking it and increasing drag.

The drag coefficient also highlights that the way wind leaves a shape is also important – ie reducing disturbance created by the shape’s lee side also decreases drag.

Fig 4: Drag also depends on the length of the Object (Source: Drag coefficient - Wikipedia)

This explains why tunnel tents can have less drag than dome tents; some highly streamlined (aerodynamic) shapes have a drag coefficient as low as 0.04!

For tents, this reinforces the need to minimize disturbance (turbulence) both upwind and downwind of our tent when we place and pitch it.

In the above examples we have assumed that the surfaces are all identical in roughness. Most tent materials are similar, and pole outside or inside the fly configurations may affect turbulence, but the impact is less relevant and significant for us so we’ll leave that for tent manufacturers to worry about. The main things for us campers to remember are:

Double the wind speed, increase force fourfold (2 squared). Increase wind speed fourfold, increase force by 16 times (4 squared).

Tent shape and orientation play an important role in reducing the likelihood of tent failure by reducing drag.

Orientate your tent to minimise the disturbance it creates both upwind and downwind.

Now, let’s apply that to real world tents and wind!

2. Tent Characteristics

You can now understand why a tent’s shape is so important in determining its wind resistance. To generalise, tents that are high with steep or vertical walls and large flat unsupported panels will fare less well in wind than low tents with many small, shallow panels that allow wind to flow over them, rather than catching in them. However, a tent’s wind resistance is a function of many factors interacting with each other, not one alone.

2.1 Panel ‘Size’

Small tents are more wind resistant than larger ones; the span of unsupported material is a major factor determining the degree to which it deforms under a certain load. Generally, tents with small, multi-angled surfaces will be more likely to shed the wind and retain their shape than tents with larger unsupported spans when those larger areas are exposed to the wind.

A flat panel that’s twice as big will experience twice the load… but in high wind that load that is already significantly elevated.

Stratospire Li in Tasmania. The Stratospire Li is one of very few double wall DCF tents as most are single wall or hybrid designs.

Non-freestanding tents pitched with trekking poles vary in panel size. The hexagonal Stratospire Li tent has many small, shallowly sloping panels that resist wind well, compared to the Triplex tent which has two very large, rectangular flat panels that are more prone to deformation.

Panel size is particularly important in non-freestanding tents because they rely on tension to maintain panel shape, rather than supporting poles under the fabric. Small panels tension more and deform less than large ones, which is why our Duplex is significantly more wind-resistant than our Triplex.

Our spacious Triplex performing perfectly in the Flinders Ranges, South Australia. We also chose it for our Bibbulmun Track thru-hike which largely comprises sheltered campsites in benign terrain.

However, it’s not that straightforward. For those interested in details (skip to 2.2 if you’re not), Dan Durston of Durston Gear elaborates:

“Although people tend to treat tent panelling as black and white based on size and number of panels, it’s more complex. A tent with a big flat side panel is one large panel, but what if we add a vertical seam up the centre? It is now two pieces (or "panels"), but still acting as one. And we'd probably say it’s one, even though it's arguably two.

“If you stake this seam at the bottom to create a line of tension up the panel, this reduces deflection and somewhat isolates behaviour of the halves. It’s still a large flat side but more would agree it’s two panels. Yet the same surface with the same stake point without the seam is considered one panel even though load and aerodynamics are identical.

“What if we add a slight bend along this vertical seam so the two sides are on different planes? Now it’s two panels even though the shape is hardly changed. What about a slightly bent shape without the seam - debatable again. My points are:

adding a seam or a slight bend does little yet might be considered as more panels,

adding a line of tension across a panel via a hem stake point is not considered to be more panels yet does help

“For these reasons, two tents can have different panel ‘counts’/panel ‘size’ without differing greatly in their wind performance.

The X Mid 1p v 2 is stable with 4 stakes but can be pitched with an additional 10 (Image Credit: Durston Gear)

“For example, the X-Mid’s end wall panels have a stake point centre bottom. Without that stake point, it behaves as one panel. With the stake point used for a line of tension partially isolating the halves, does that make it two panels? Most people would say no. If I added a seam that did nothing other than create a seam, many people would now say yes, even though the stake point helps while the seam does nothing.

“Black Diamond's Beta Light has big flat sides, slight bends breaking them into three almost flat panels. Without seams and/or slight bends it’s considered one panel. Either way, wind performance is similar. The mere existence of seams and greater panel count do not constitute a meaningful improvement over another tent classified as one big panel when it really is almost identical:

Flat or angled panels? Image Credit: Black Diamond, Dan Durston

“Hence, in non-freestanding tents, large panels can be supported by creating lines of tension across them to mimic smaller panels, while smaller panels are not a substantial improvement if they are created by only slight bends in shape.”

So as Dan nicely explains, more panels alone do not guarantee a better wind-performing tent.

Therefore, when pitching your tent, remember that more significant bends and angles, smaller surface areas and shallower slopes facing the wind reduce drag. Such panels retain their shape better when compared to flat or near-flat steeper panels, and thereby reduce wind-loading (see panel steepness and orientation below).

The Stratospire Li has strongly angled panels such that a relatively small area faces directly into the wind at any one time (Image Credit: Tarptent)

For freestanding tents, all things being equal (and often they are not), those with many poles, closely-spaced poles, or crossing poles will be more wind resistant than freestanding tents with fewer because they increase the supported area of tent material.

2.2 Panel Steepness

The closer a panel is to vertical the more drag it has, and the more it will be impacted by wind (but see 2.3 below). Low tents with gently sloping panels fare better in wind than taller ones with steeply sloping panels, but do less well with snow loading.

2.3 Tent Shape and Orientation

Certain tent designs are famous for their wind resistance. The pyramid is one of these. Its walls are relatively steep but the bulk of the material is close to the ground, where wind speed is lowest due to wind shear. Triangulated designs are also famously strong and tension well along seams, with less deformation in wind than rectangular ones. A number of readers have pointed out that pyramids and modified pyramids with more than 4 sides, such as MLD’s Trailstar or Luxe’s Hexpeak are even more stable, with smaller surface areas facing directly into the wind.

Mountain Laurel Design’s low profile, highly wind-resistant pentagonal Trailstar

3-4 pole tunnel tents (2-pole slightly less so) and geodesic domes with aerodynamic vestibules are also famous for their excellent wind resistance when correctly oriented, and are shapes of choice for mountaineering tents: see the Aussie-made Mont Epoch tested to 139.8 kph (86.9mph).

Many years ago we won a Macpac geodesic tent, and it too doesn’t budge or deform even in strong winds. It’s a three-person, 4-season tent that also handles snow loading:

The Macpac Aspiring Tent’s aerodynamic vestibules improve its wind resistance when correctly oriented

Non-symmetrical tents are not uniformly wind resistant in all of their aspects, so correct orientation to the prevailing wind is important.

Tunnel tents are usually pitched back end into the prevailing direction with the narrow end deflecting the wind like the prow of a ship (also, the wind doesn’t blow up your tent when you unzip the door!). Four-season tunnels can be surprisingly solid side on as well with strong, closely-spaced poles allowing the curved walls to deflect the wind up and over, rather than deforming and cupping to catch the wind.

Do you know your tent’s best orientation? If you’re unsure, remember the ship prow – where might it be on your tent? Where are the largest, steepest panels that should be parallel to the wind?

Note the different results for different directions. Why is the smaller model less wind resistant than the bigger ones, can you guess? Answer in the link along with short video of the tests.

Image Credit: http://thetentlab.com/MoonLightTents/Strength.html

This is a non-freestanding wind tunnel test that’s worth listening to, as well as watching. Strong winds can also cause panels to slacken on the downwind side of non-freestanding tents, creating a feedback loop that exacerbates dynamic loads.

And here is a tunnel tent test; we can’t vouch for the brand, but it is a classic design.

Winds often change direction during the night and, if you’re sufficiently familiar with prevailing weather patterns or have accurate forecasts available through, say, your Inreach, you can accommodate it. We did this in Landmannalauger, pitching our tent for the forecast direction of the storm, rather than the direction at the time we pitched.

2.4 Tent Poles

Semi-freestanding tents with one curved pole are more prone to failure than freestanding tents with more poles; this makes sense as the wind loading is spread across more poles with less loading on each when there are more of them, and unsupported fabric area is smaller.

Strongly curved poles are stronger than shallowly curved ones (but increase drag). Shorter poles are stronger than longer ones.

Pole material and diameter also affect strength: larger diameter stronger than smaller, with various grades and thicknesses of aluminium and carbon also affecting strength. DAC are industry leaders in aluminium poles whose alloys have an optimal combination of strength/rigidity/flexibility that are used by many quality tent manufacturers. Pole quality is one of the first places budget tents cut corners.

Crossing poles in geodesic tents support each other and, the more crossing points, the stronger the structure.

Our Macpac Aspiring tent has five poles and 10 crossing points to create a highly stable structure. Image Credit: MacPac

Some four season tents (eg Hillebergs) have wide sleeves to allow for doubling up of poles, making them incredibly strong.

Tarptent’s Rainbow and Double Rainbow have apex grommets for the addition of trekking poles to significantly strengthen the structure. The SlingFin Portal freestanding tent uses velcro to similar effect.

Tarptent’s Double Rainbow with trekking poles added for improved snow loading and wind resistance. (Image Credit: Tarptent)

How poles are attached to the tent also makes a huge difference to their strength and the support they provide. Tent poles in sleeves spread support and load along the entire sleeve (but are harder to insert especially in high winds); widely spaced clips less so.

In the Soulo tent, Hilleberg’s clip attachments spread support of the tent over a large area without using sleeves except towards the base of the tent.

There are also a large number of clips to spread the force along the pole. This system prevents the abrasion of fly undersurfaces that happens in tent designs where the fly is thrown over poles attached to the inner, and then fastened down. Wear occurs where the fly is stretched over the poles. (Image Credit: Hilleberg).

Non-freestanding tents generally use trekking poles which are under compression in a triangulated structure, so they are incredibly strong and pretty much over-engineered for the job; the tent is likely to fail before the poles, or the tent will deform to such an extent that the pole is no longer held securely and it will suddenly pop out of alignment, causing a catastrophic failure cascade. You are more likely to break them by bumping hard against them; the wind is unlikely to do this on its own although this video shows an exception at 5:24.

The Duplex has an optional freestanding Flex kit of poles that, according to Joe Valesko, “…help to brace the walls against the wind. They are even more effective combined with trekking poles bracing the peaks. I wouldn't say they are required, but they definitely help in places like Iceland where the terrain is wide open.”

Joe adds that it’s possible to add a guyline where the poles cross to help keep them braced, but that it’s rarely necessary:

“I know that it is possible for the poles to "flip" inward if they are under enough load, but I think the only time I've seen that happen in testing is under several inches of wet snow load when the tent was unoccupied. The normal wall guy line does also help.”

Duplex Flex pitched in a windy spot in Europe (Image Credit: Zpacks). Note deflection of the right front vestibule and side, and the support being provided by the crossing point of the poles.

When we pitched our Duplex for an Iceland storm, we attached a guyline to the door panel tie out in the centre of the panel being deflected above, even though it isn’t an official guy point.

2.5 Panel Tension and the Importance of a Taut Pitch

A taut tent deflects wind more effectively than one which is loose. At a certain point, wind deformation cups the tent fly, catching the wind like a sail instead of deflecting it. At this point, load on the tent increases abruptly; see this video at 1:10 (the whole video is worth watching and listening to).

Figure 5: Drag and the Effect of Deformation (Source: Drag coefficients - Wikipedia)

The significance of limiting deformation is illustrated by our drag coefficient (Fig 5). Recall the drag coefficient for the hollow hemisphere: if the shape deforms to a flat face the coefficient increases from 0.38 to 1.15 and the forces increase correspondingly. If the surface deforms further into a cup, the drag coefficient increases to 1.42, demonstrating the importance of maintaining panel shape. Smaller panels potentially make this easier to achieve but, irrespective of panel size, the example highlights the importance of a good tight pitch for whatever tent you own.

A flapping tent is also more likely to tear, and guy lines and guy attachment loops more likely to abrade against each other and against the stakes. Stakes themselves are more likely to be tugged out.

Large unsupported flat panels such as on the Triplex simply can’t be tensioned to the same degree as smaller panels of, say, the Duplex. With their smaller panels, solo model equivalents from ZPacks, Durston Gear and Tarptent (Plex Solo, XMid 1 pro, Aeon Li) will all be more wind-resistant than their big sisters.

Like all little sisters and all else being equal, the XMid Pro 1 will be more wind resistant than her big sister the Pro 2. (Image Credit: Dan Durston)

2.6 Tent Materials and Wind

Silnylon, silpoly and DCF (dyneema composite fibre) are three commonly used tent materials and each has specific advantages and disadvantages. However, tent materials are highly technical and, frankly, beyond our expertise other than this section in which we ask four cottage manufacturers their thoughts.

Manufacturers are genuinely passionate about the materials they use, selecting for a combination of weight, waterproofness, durability and strength. With their fascinating contributions, this section became longer than War and Peace so, if you’re less interested in technical details, skip ahead to 3 below.

Henry Shires of Tarptent writes,

“The advantage of silnylon is that it is best able to absorb and distribute wind load such that the stress on any one concentrated surface area is low and the chance of a fabric tear is low. That is the result of inherent stretch in nylon fibres.

“Slingfin uses a fly with 10D Nylon 66 Ripstop Sil/Sil 1200mm. 10D isn't as strong or abrasion resistant as 20D or 30D and it has to do with how much material is actually present. I will argue that the fabric is really minimalist with low pressure rating — which will drop below 1000 after some use — and minimal abrasion resistance. There is inherent movement in any tent with a fly draped over a pole structure.

Fabric Denier (Image Credit: Tarptent)

“Polyester fibres have very low stretch (although there is/can be plenty of bias stretch) so more care needs to be taken in design to reinforce pullouts and other stress points.

“Lastly, Dyneema is also extremely low stretch in the fibre grid but there is inherent non-recoverable stretch/deformation in the mylar layers so care must be taken in design to reinforce stress points and orient the fabric panels such that wind stresses are concentrated along the fibre grid as much as possible.”

Stratospire Li near a pass in the Tassie highlands. The wind howled through overnight.

Tim Hunt of SlingFin says,

“It’s hard to make exact claims about how much stronger silicone coated fabrics are since there’s so much variation between fabrics but, generally, silicone coated nylons are about 15-25% stronger than sil/PU or sil/PE coated nylons of similar weights in our testing.

“Sil/sil fabrics achieve better tear and tensile strength than other coatings due to the way they interact with the individual fibres in a fabric. The slick silicone allows fibres to slide over one another, so more fibres are recruited to distribute force, similar to why nylon is generally stronger than polyester on a weight for weight basis. Coatings like PU or PE lock fibres in place, and point stress like a tear is concentrated in fewer fibres, which are consequently more likely to fail.

“Sil/sil nylons also sag much less than their sil/PU nylon counterparts.

“Another thing we’ve learned from extensive fabric testing is that, while generalizations are common, fabrics that look similar on paper vary enormously in actuality. It’s true that 10D fabrics are considered light, and many 10D fabrics don’t offer sufficient durability for flysheets, but we selected our 10D after testing a huge variety for different metrics.

SlingFin testing fabrics for UV resistance (Image Credit: SlingFin)

Strips were removed after set periods and tested with a tensile tester for strength. (Image Credit: SlingFin)

“Our 10D NY66 sil/sil has a tensile strength comparable to some 30D sil/sil nylons we’ve tested, and far exceeds much heavier fabrics with different (sil/PU or sil/PE) coatings. It’s far stronger than any 20D polyester we’ve tested, regardless of coating. It was also the most UV-resistant non-titanium dioxide coated fabric we tested, which was shocking, since lightweight fabrics normally have much worse UV resistance than heavy fabrics.

SlingFin Portal 2 with a bit of snow (Image credit: SlingFin)

“Interestingly, the polyesters we tested underperformed comparable weight nylons, counter to universal assumptions about polyester’s superior UV resistance (again, generalizations are risky!).

“I think there’s a spec-driven arms race with regards to hydrostatic head numbers. It’s an easy quantitative metric to say one fabric is worse because the number is lower.

The pressure needed to push water through even 800mm-rated fabric is just over 1 psi, far higher than you’ll ever experience on a flysheet unless you stand on it. In floors, it’s possible to exceed that, but I believe the idea that you need HH ratings in excess of 1200mm for flysheets is rooted in shortcomings of PU-based fabric coatings. PU wets out over time, and the higher the HH rating, the longer it takes.

PU also weathers much faster than silicone (PU is an organic polymer and therefore much more susceptible to UV damage) so it’s wise to start with higher HH ratings when using PU coatings to compensate for faster breakdown of the coating. Silicone coatings do lose waterproofness over time, but the slower rate of degradation means it’s unlikely to be the failure point of the tent.” Read more of Tim’s thoughts here.

Joe Valesko of Zpacks writes,

“DCF material has a higher tear strength compared to silpoly or silnylon, so it can handle high wind without tearing. It is just a matter of keeping your stakes in the ground, and ideally pitching with the wind at the head end of the tent.”

Duplex in the central highlands of Iceland on the Laugavegur Trail

And Dan Durston of Durston Gear writes,

“With traditional fabric, 40-70 denier weights are typically excellent for handling high load and common on 4-season tents. 20-30D fabrics do well for a capable 3-season tent, while 7-15D fabrics are very lightweight materials that are typically inadequate for high wind usage unless the strain is quite low.

“Traditional fabrics stretch under load, which has the advantage of dispersing stresses, but also allows more panel deflection, movement, and buffeting. A small bit of stretch can help, but generally stretch is a negative as it makes for a noisier/less comfortable shelter that is buffeted more by the wind.

“Composite fabrics like DCF offer greater strength and low stretch, but in the case of DCF the stresses must be aligned with the material's fibres (rather than acting diagonally or "on the bias") because DCF will stretch, deform, and eventually delaminate if it is substantially and/or repeatedly stressed on the bias.

“With a trekking pole tent the major stress lines run between fixed points (stakes and pole peaks), which means the stress lines can be along the seams but also diagonally across panels. Look for a DCF tent that orients this stress inline with the fibres and, when that is not possible (with every tent there will be seams where this is not possible), then that seam should be reinforced against deformation with DCF-backed tape.

“A related issue with DCF is guylines that pull ‘out’ on a panel. Pulling outwards on the material causes permanent deformation and eventually fatigue and failure, similar to pulling on the bias. Side panel guyouts positioned in the middle of a panel should only be used very gently and with shockcord on the guyout point to dampen buffeting without putting substantial pull on the material.

“The X-Mid’s side panel guyouts are positioned along a seam where the side wall steepens, so the guyline can be oriented on the same plane as the roof panel. Therefore, the side panel guyout can be staked out so it is both inline with the fibres and on the same plane as the roof panel it is pulling on, which makes it both effective and robust against material damage:

XMid Pro 2 showing alignment of guyline tension along the fibres (Image Credit: Dan Durston)

DCF may be very strong but has poor abrasion resistance, so Geoff and I keep our tents scrupulously clean by always using a footprint, and folding and rolling rather than stuffing the tent into its bag, just as hang glider pilots have been doing for decades. Yes, wear develops along folds, but this is still less damage than that caused by repeatedly scrunching the entire sheet of material.

Clearly, each tent material has inherent strengths and weaknesses that specific design/manufacturing can enhance and minimise respectively, and tent designers choose materials that best match their priorities for each tent they make. There is no single best fabric, only fabrics best suited to specific uses and designs. Understanding the strengths and limitations of your own tent material, whatever it is, lets you maximise its performance in strong wind.

3. Budget, 3 Season, 4 Season, Ultralight, Alpine, Expedition or Mountaineering Tent?

The etymology of mountaineering, alpine, expedition and 3/4-season tents is confusing, and the terms are regularly used interchangeably. However, every tent is a compromise between often contradictory requirements such as liveability and interior space vs weight and minimal footprint, snow-shedding ability vs wind-resistance, simplicity of setup vs stronger anchoring, ventilation/condensation management vs waterproofness, price, and many more considerations. Different tents meet different consumer priorities, sacrificing some features to enhance others; manufacturers often classify their tents into categories indicating their design priorities.

SlingFin Crossbow somewhere, with a bit more snow (Image Credit: SlingFin)

Regarding ultralight tents, Dan Durston of Durston Gear says,

“The wind performance of a tent can be thought of as two components: how much wind drag the tent has, and how well the fabrics and pole structure can handle the resulting load. A tent has low wind drag if it is small, low, and/or sloped (so the panels are not broadside to the wind) and has high wind drag if the opposite is true. A tent with high wind drag has poor wind performance - unless the fabrics and structure can handle the resulting higher load.

“Hence, there are two paths to good wind performance (low drag and/or high strength) such that we see very different types of tents being good in high winds.

Hilleberg tents are famously bombproof; with their heavier fabrics, poles and guylines, they aren’t ultralight.. but this is not the brand’s prime aim. Image Credit: Tristan Tempest

“Classic heavy dome tents have a lot of drag but also very strong fabrics and poles. On the other extreme are pyramid tents which are highly regarded for wind performance even though they have relatively minimal structure, often lighter fabrics, and larger panels because the single pole structure gives them low volume/drag (but also low headroom). Opting for a low drag tent can be a good ultralight solution but does mean trade-offs in headroom/living space as well as snow shedding (low angled panels shed wind but catch snow).

“The X-Mid is designed as a generalist (or ‘all-round’ shelter) rather than specializing for certain conditions. As such, it doesn't trade-off headroom and snow shedding for increased wind performance to the same extent as a traditional pyramid tent. The X-Mid shape has steeper walls which does result in greater wind drag in exchange for more living space.

“While the X-Mid has more drag than a traditional pyramid and thus will see more wind force on the tent (e.g. greater wind buffeting), this is partially offset by the increased structure (two poles instead of one) and greater ability to support the tent with peak guylines. With two poles, the canopy is more supported and the strain is not focused on a single point.

Thus pyramid tents have the advantage of lower drag while the X-Mid has the advantage of greater structure. The overall net effect is debatable but single pole pyramids are generally better in very high winds and can be thought of as more 'wind specialist' shelters while the X-Mid does well but is balancing wind performance against other considerations like liveability.”

Budget tents may survive heavy rain and modest wind but are – and Geoff and I nail our colours to the mast here – universally useless in high winds.

Even though many are made in the same factories as more expensive tents, corners are cut. Lower quality fabrics, lower grade and/or narrower poles, inferior stitching, poorly or unreinforced stress points, and fewer and/or poorly placed guy attachments all ensure these tents succumb to forces they simply aren’t built to withstand. A knockoff Lanshan or Naturehike may perform as well as a Duplex or MSR in benign conditions… but will be noticeably inferior in strong wind.

Those on a budget will, in our opinion, be better off buying a secondhand quality tent rather than a new budget one if you expect to regularly encounter strong wind.

This $14 Kmart Tent with fibreglass poles may not survive two hours with a two-year-old, let alone strong wind! This review confirms it is a fair weather or car camping tent.

Many 3 season tents can withstand relatively strong wind, but they vary enormously. As we’ve seen, Youtube videos are unreliable for actual numbers; few manufacturers publish wind tunnel test results (if only there were a W-rating for tents as there is an R-rating for sleeping pads!).

It is unrealistic and unreasonable to expect even the best 3 season tents to perform well, or at all, in conditions they are simply not designed for. If regularly heading into conditions where storms include strong winds, snow and exposure, you’re risking your life to expect an ultralight single wall dcf tent to provide sufficient protection like that of geodesic tents nearby (jump to 5:04 and 9:34).

Four season tents are designed to withstand snowloading, but not all of them perform equally well in strong winds.

The One Planet Polar Dome is designed for extreme conditions. Why is it so heavy? The fabric is 250D for durability! Image Credit: David Etheridge

Mountaineering tents/expedition tents withstand strong wind as well as snow; many are also designed to be left set up for long periods of time. However, such bombproof tents with thicker, stronger fabrics, more and stronger poles, and many more guy lines and stakeout points come at a significant weight penalty: the one planet 3 person polar expedition tent weighs 8.5 kg; most 2-person alpine/4-season tents start at around 3 kg.

Some goldilocks tents such as the Slingfin Portal are a compromise: designed for strong winds and somewhat heavier than ultralight tents, but not as heavy as true 4-season, mountaineering or expedition tents. The Slingfin Crossbow is heavier and has alternative options so it can be pitched all-in-one and in 3 or 4 season configurations.

The SlingFin Portal might look the same as many tents of similar design, but utilises trekking poles plus other features, such as ten upper level guylines plus four internal ones, that make it more wind-resistant. Image Credit: SlingFin

Many quality all-round tents such as MSR’s Hubba-Hubba are surprisingly decent in moderate wind especially when well-pitched.

Most of us own a tent that suits our needs 95% of the time, but we are simply caught in winds that are stronger than we expected on a particular trip. This series of articles aims to help you choose and understand your tent, how it behaves in wind and why, and how to get the most out of it in windy conditions.

Finally, no matter what your tent, it will be useless without an accompanying skillset, and a skilled camper with an average tent will always fare better than an unskilled one with a top-end tent. Just because you’ve bought a bombproof 4-season tent, it’s still important to avoid conditions you lack the knowledge to handle.

Read on to build that skillset in Part 2: How Wind Interacts with Terrain and How to Identify a Great Pitch, followed by

Part 3: How to Pitch Your Tent For and During Strong Wind.

See also our companion article Understanding Weather Apps and Forecasts for Hiking for usesful baseline information on wind forecasts, the Beaufort Scale, Wind Chill, App selection and more.

And, if you’re hiking into challenging conditions, your gear won’t save you if your decisions are bad. See our Human Factors and Decisionmaking for Hiking Safety to hike another day!